Doug Carson, Senior Advisor to BWI Group in Q&A session

Doug Carson has been involved with MagneRide suspension system since 2005, as Chief Engineer. He was responsible for the launch of the suspension technology into Europe. Carson later became Chief Technology Officer. In this Q&A, he reflects on MagneRide’s engineering breakthroughs that defined the award-winning suspension systems.

Q: Where did the idea for MagneRide come from?

The concept of using magnetorheological fluid for damping goes back decades. But it wasn’t until the 1990s that the technology became viable for automotive use, thanks to advances in materials, electronics, and control strategies.

MagneRide became a viable alternative and the idea of a valveless damper, controlled purely by a magnetic field and software, was incredibly compelling. It promised levels of control and tuneability that simply weren’t possible with other semi-active technologies.

Q: When did development of the MagneRide really start to take off?

The first big step was around 1995, when MagneRide dampers were put on a Chevrolet Suburban. In the very early trial, the ride quality wasn’t perfect, but the response and authority of the system were there and it showed some real potential.

After experiencing the technology firsthand, teams from Cadillac and Corvette were eager to put it into production. Finally, the first programme went into mass production with the 2002 Cadillac Seville STS.

Q: What were the major technical challenges during development?

This really was a semi-active suspension system like no other so there were a lot of challenges to overcome. Magnetorheological fluid is full of iron particles, which meant we had to rethink materials entirely. We adapted several parts, including gas cups, cylinder tubes and rod guides. We were also developing new control algorithms and adapting to the demands of automotive production.

Q: How did MagneRide stand out from anything else on the market?

With MagneRide, there are no internal valves or complex flow channels. The increase of damping force comes from altering the characteristics of the magnetorheological fluid with a magnetic field. That means faster response times, just milliseconds, and no moving mechanical components to wear out or fail.

MagneRide makes OEMs’ development faster, more flexible, and more cost-effective. It’s fully software-controlled. You don’t need to manufacture new parts to tune the damper, you just plug in a laptop and adjust the calibration.

Q: How was MagneRide received by the industry at launch?

The system won a string of industry awards: the Popular Science “Best of What’s New” in 1999 and 2002, the 2003 PACE Award.

Besides Cadillac, MagneRide was also installed in Ferrari. That was great validation for us, if Ferrari wanted MagneRide then clearly, we were onto something special. From there, it spread quickly to other major OEMs, including Lamborghini, Audi, Honda, and Ford.

Q: How has MagneRide evolved over the years?

A major area of progress has been the secondary ride, which is the ability to filter out small, high-frequency inputs that affect NVH and comfort. That’s especially important for modern EVs, where cabin noise is low and every bump is more noticeable.

Besides, the fluid is now better performing, the damper architecture is refined, and the control algorithms are much smarter.

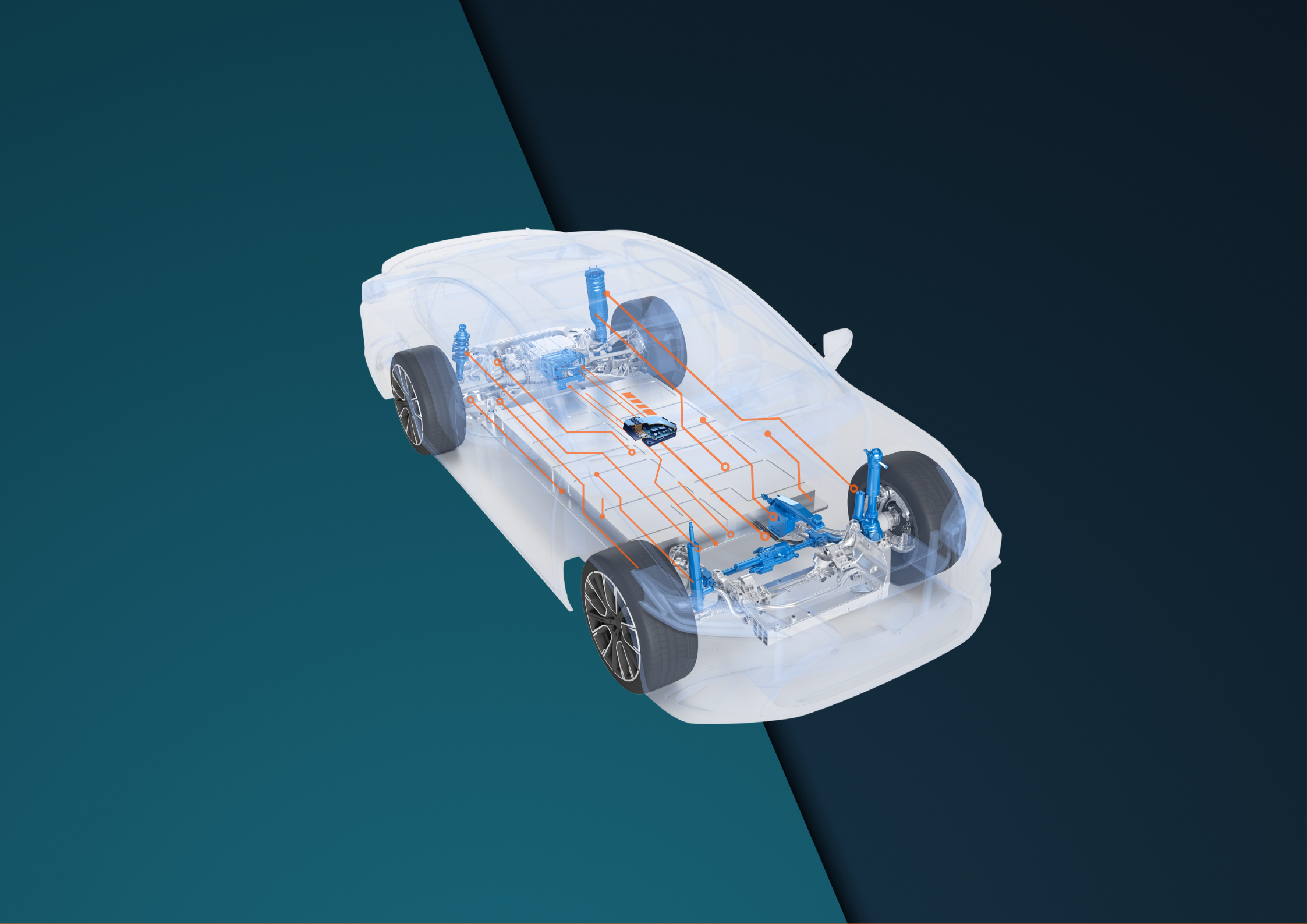

We’ve also made the system much more modular and flexible. OEMs can choose full-system delivery, including software, sensors and ECUs, or just the dampers. That flexibility helps OEMs integrate more easily with centralised vehicle architectures and software-defined platforms.

Q: And what does the future hold for MagneRide?

The developments in secondary ride have enabled MagneRide to be applicable to more vehicle segments. The rise of heavier vehicles has also increased the demand for more sophisticated suspension technologies. As a result, MagneRide is now being used on everything from SUVs, hatchbacks, saloons and sports cars.

We’re also working on smarter integration. As vehicles become increasingly software-defined and connected, MagneRide can play a bigger role in predictive control to use data in real time to adjust settings based on the road ahead.

We are also leveraging AI to further accelerate the tuning phase. It means that when we get to tuning on the track, in the real car, the algorithms are already very mature.