Article published in Vehicle Dynamics International, May 2025 Issue

CLICK TO READ>>> Cost effective suspension technology

CLICK TO READ>>> Cost effective suspension technology

Sept. 12th, 2024, Krosno, Poland

On September 12th, current and former employees, BWI Group management and invited guests took part in the celebration of the 80th anniversary of the shock absorber factory in Krosno. The plant is today not only one of the largest production facility in the BWI Group, but is also, with impressive statistics and decades of experience, a proven and reliable partner supplying globally the automotive industry with innovative suspension solutions.

„Our strength comes from values we stay aligned with. Innovation, quality and customer care are the pillars on which we have built our reputation”. says Dariusz Kucza, Plant Director.

80 Years of History

The beginning of the plant is back to 1944. After years of wartime turmoil, workers returned to the destroyed rubber factory to restore production and revive the spirit of the industry, so much needed in Poland at that time. Initially, the activity was focused on the repair of agricultural equipment. By the end of the 1950s, the Polish government decided to narrow down the production to the manufacturing of spring elements for motorcycles and telescopic shock absorbers. In 1958, the first shock absorber was produced in the Krosno factory, and in 1969 the site was officially named POLMO. In 1997, the American Company Delphi Automotive Systems took over the facility. Under this new name, Krosno plant acquired new customers and modernized its production processes. The development and strengthening of the plant continued with a redoubled intensity when BWI Group became the new owner of the site in 2009.

New challenges

80 years of existence makes the Krosno factory not only the witness of the history, but also shows the transformation that Poland went thru the last eight decades. During the post-war time, there was a giant demand for reviving the industry, while facing a lack of resource and tools required for an efficient operation. Then came the time of privatization of the industry by the end of the 20th century, when foreign capital and modern technologies entered Polish industry. Today in the hands of BWI Group, the manufacturing facility entered into a new chapter with operation based on Manufacturing 4.0 solutions, the highest quality standards and the newly adopted Sustainability policy. In this regard, the plant began its transformation last year towards 50 percent reduction electricity carbon emissions, as well as a 15 percent reduction in production waste by the end of 2024.

Today’s Products and Customers

The factory is currently supplying to major OEMs automotive suspension components, including various shock absorbers and struts, controlled dampers such as MagneRide® dampers, Semi-Active Roll Control systems, Magneto-Rheological engine mounts, but also Electronic Control Units and sensors, which enhances the BWI Group’s ability to develop electronic and electrical architectures. Krosno is delivering to 46 customers in 97 locations worldwide. Among these customers are BMW, Stellantis, Ford, GM, Audi, Volvo, VW, Ferrari and Lamborghini.

The plant in Krosno is one of the largest employers in the Sub-Carpathian region, and its long history makes it also one of the most recognizable and significant industry company of the Polish economy. With more than 300 million units produced since its debut, the plant has not only gone thru the history of industrial development in Poland, but also contributed to it.

“None of our successes would have been possible without the people who made and make this plant. Let me express my great gratitude to all – employees, both those who have been with us for years and those who have joined us recently. It is their hard work, commitment and loyalty that are the foundation of our success.” adds Plant Director expressing his gratitude towards the Staff.

About BWI Group

BWI Group’s is one of the market leader with high quality brake and suspension products and have been recognized by more than 50 global automakers. Thanks to the progress on technological breakthroughs, business development, and production, The company’s total order value rocketed by nearly 300% year-on-year in 2023. The company’s solid development has benefited from the integration of its global resources from three continents, Asia, Europe and North America, to empower global smart mobility. With a heritage reaching back over 100 years, BWI Group is now operating a total of 9 production bases, 7 research and development centers, and 1 software center worldwide.

In the era of Industry 4.0, data has become a crucial factor driving production efficiency across all industries, including automotive leader in the engineering and manufacturing of advanced suspension and brake systems, BWI Group leverages the power of data analytics to optimize manufacturing processes, increase efficiency and deliver quality and price optimized components to its customers.

Challenges of today’s automotive component manufacturing

Today’s automotive industry exposes manufacturers to unprecedented challenges. The growing pressure to reduce cost while maintaining the highest standards of quality and safety requires innovative approaches to production management. The ability to quickly process and analyze the massive amounts of data generated by modern production lines is key to meeting these challenges. Properly “cleaned” and processed data has the potential to be converted into decision-making processes that lead to actions, contributing to the improvement of quality, efficiency, and reliability of production lines.

Production Data Management at BWI Group

At BWI Group, we are using a data analytics system developed by the Operational Technology Engineering team, which is based on advanced tools to efficiently and reliably manage information from the manufacturing process. With our system, we achieve:

This includes identifying the causes of downtime, quality issues, and performance and availability losses. The OPC (Open Platform Communications) systems are used for data acquisition from machine controllers and automation equipment, providing precise and up-to-date insight into production processes. All events are automatically reported, minimizing the need for manual data entry and reducing the risk of errors. Additionally, the data for subsequent analyses is sourced from Single Point of Truth, ensuring a consistent and reliable foundation for continuous improvement and decision making processes in production environment.

This includes a continuous improvement process, managing suggestions and building on lessons learned. BWI uses the Daily Management System to manage tasks and coordinate actions, allowing for effective monitoring of progress and the implementation of corrective actions. Since the environment is consistent with what is used at all levels of the organization, data flows in an organized manner without loss of information.

This ensures an integral and reliable flow of information. Data is processed in a hybrid model both in the cloud and using internal server capacity, improving scalability and security in information management. The solution supports the entire process from problem identification on the production line, through the implementation of corrective actions, to sharing the acquired information with other plants.

These dashboards are optimized for different organizational roles and offer various levels of detail, enabling quick and easy analysis of key data and decision-making based on current information.

This advanced approach allows for effective production management, process optimization, and quick response to changing conditions, ultimately contributing to the increased efficiency and quality of BWI products.

Customer Centered – The Customer comes first

Improving processes through the deployment of advanced data analytics results in the single most important end outcome, which is the satisfaction of our customers. Let’s list a few of the many benefits:

BWI Group announced on July 10th its “All-by-Wire 2035” global strategy: provide global customers with more smart mobility solutions, leveraging its expertise in brake-by-wire, active suspension, and intelligent systems and architectures. The group expected 95% of the chassis products delivered in 2035 will be fully controlled by wire.

As one of the latest milestones, BWI Group secured two OEM partnership on Electro-Mechanical Braking (EMB) system, and planned to be massively produced EMB for the customers in 2026.

George Chang, CEO of BWI Group, said, “BWI Group is dedicated to advancing the electrification and intelligent connectivity of the automotive industry globally, through continuous investment and promotion in the two core areas of highly automated driving and extremely comfortable smart cockpits.“

He outlined that BWI Group’s brake-by-wire products, providing robust safety redundancy, will support L4 and higher levels of automated driving technology; full active suspension products will help build multi-functional and highly comfortable smart cockpits for multi-scenario. Meanwhile, automotive systems and architectures will fulfill the demands of the intelligent transportation era by building integrated hardware-software systems and centralized electronic-electric architectures.

Particularly in the field of brake-by-wire, EMB is a key product for BWI Group and represents a key innovation. BWI Group will complete prototype A development in 2024, establish an automated production line in 2025, and begin mass production for customers in 2026.

Throughout the continuous upgrading of brake-by-wire technology, BWI Group’s ultimate EMB technology has accumulated over 20 years of experience. Thanks to predecessor’s concept validation in 2000, the group’s technology has now evolved into its third generation. To meet market demands, BWI Group entered partnership with ThyssenKrupp Steering, joining forces to leverage each other’s strengths and accelerate the research, development, and production of EMB.

Jiang Yongwei, BWI Group China President, said, “Our Chinese EMB R&D team is improving the performance and durability of the EMB technology to ensure a higher level, and will achieve breakthroughs in the next generation hardware and software this winter.”

BWI Group’s R&D centers located in the United States, Poland, Italy, and China, are in collaboration with the Shanghai Software Center, and jointly advance EMB research and development. BWI EMB underwent winter cold-weather testing in two consecutive winters in 2023 and 2024.

Leading automakers in North America, Europe and Asia have witnessed the testing and gave very positive comments and feedback about the cutting-edge technology and reliability.

BWI Group will carry comprehensive performance tests, including durability tests, adaptability tests in varied adhesion conditions, and stability tests in diverse environmental conditions, to ensure EMB’s outstanding performance in various scenarios. Subsequently, the product will strictly follow BWI Group’s rigorous process for design validation and production validation, to ensure every stage from concept to production meet the world-class quality standards.

Doug Carson, CTO of BWI Group said: “A large amount of investment was made in our EMB research and development, testing, and production to better realize the eco-friendly, zero-drag, and full-redundancy characteristics. Our dual-motor design boasts the solid R&D which started very early and stands out with its capability to significantly accelerate braking response.”

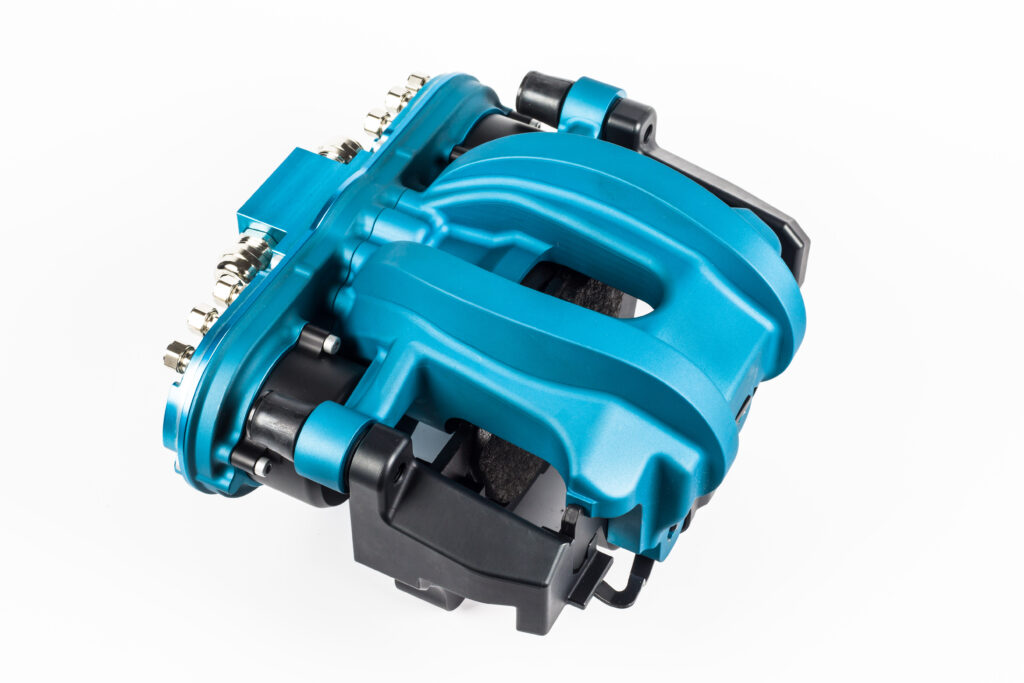

BWI Group’s EMB not only features sleek design, agile response, hardware redundancy, scalable solutions, but also utilizes a fully redundant hardware solution in all-dry format for four wheels. The BWI EMB system will soon support L4 highly automated driving and above.

Powerful, safe, and stable – BWI’s EMB system integrates functions such as ABS, ESC, TCS, ACC, and advanced diagnostic capabilities to ensure safety and reliability. The dual-motor EMB system can significantly accelerate its response speed, while the four-wheel independent control maximizes braking stability.

Truly wire-controlled with a simple structure – BWI’s EMB system adopts a minimal architecture, eliminating servo mechanisms or ESC modules, to be truly wire-controlled. The system removed brake pipes, unified the left and right steering structures, reduced space requirements and enhanced the possibilities for lightweight and minimum designs.

Plug-and-play with optimized costs – BWI’s EMB system utilizes a simplified plug-in-assembly without the need to process brake fluid. It makes a vehicle much easier to assemble in a much shorter time. The system uses fewer components to bring a more cost-effective solution for L3 to L5 highly automated driving vehicles.

Environmentally friendly – BWI’s EMB system achieved zero drag by releasing the calipers instantly after braking, which effectively reduces energy consumption and emissions of carbon dioxide and particulates. The electrical signal transmission replacing brake fluid further minimizes the potential impact on the environment.

Promising EMB market prospect

Doug Carson said: “BWI’s unique EMB system has two motors, ball ramp technology, integrated electric park brake, wear adjustment features, and even scalable family approach, offers a very powerful solution to our customers.”

Customers in the U.S. and the Europe showed very strong interests in BWI’s EMB system, and eager to discuss about the cooperation. A car maker who had postponed the EMB application, but restarted the project to discuss with BWI Group. The group also received lots of positive feed backs, such as BWI’s incredibly packaged EMB is the only one fitting into its mechanical structure without any change, according to Doug Carson.

Rapidly developing Chinese automakers are actively embracing BWI Group’s world leading EMB technology. Kaiyi Auto and BWI Group announced the strategic partnership to jointly develop EMB products and technological applications. New-type smart electric vehicle maker, U Power Tech, will integrate BWI Group’s EMB system in super chassis products to expand technological capabilities and fit a wider range of vehicle.

BWI’s powerful and comprehensive EMB solution brings limitless possibilities to automobile production and manufacturing. The coming 5 years will be a critical period for EMB technology development, according to the analysis by Xiong Shusheng, Professor at Zhejiang University Vehicle Research Institute, Visiting Professor at Chinese Academy of Sciences.

Xiong Shusheng predicted EMB market penetration rate may reach 5% in 5 years. In the next decade, it will experience explosive growth, contributing an estimated billion-dollar worth 20% share to the global brake-by-wire market valuing tens of billions dollar.

He points out that BWI Group has taken the lead in the fully dry EMB technology sector, combining the technological advantages of joint research and development between the Europe and the US with the cost advantages of China manufacturing, positioning it to capture a larger share of the EMB market in the future.

Facing the promising market prospects, BWI Group is full of confidence and anticipation for EMB’s future development, and looks forward to working with all parties and embracing the great future. BWI Group advocates for suppliers to work together and jointly promote the development and innovation of EMB technology, aiming to create an open and prosperous EMB technology ecosystem.

April 9, Budapest. BWI Group, a world-leading tier-1 intelligent automotive chassis supplier, and thyssenkrupp Steering, a global tier-1 automotive partner for steering solutions signed a contract for the development and manufacture of a pioneering Electro-Mechanical Brake (EMB) technology. This collaboration aims to further advance Level 3 and above autonomous driving brake capabilities.

The long-term cooperation will pave the way for further chassis-by-wire collaboration. The technical synergies will drive the future of X-by-wire chassis systems and enable the transformation from assisted to autonomous driving by enhancing safety, comfort and efficiency.

George Chang, CEO of BWI Group, and Patrick Vith, CEO of thyssenkrupp Steering, formalized the agreement in Budapest, Hungary, on April 9. Executives from both companies were present at the signing ceremony.

“We at BWI are excited about the future of chassis-by-wire,” said George Chang, CEO of BWI Group. “We are pleased to be collaborating with thyssenkrupp Steering on this truly innovative technology, leveraging our expertise in braking systems since 1934 and our century-long heritage of chassis technology innovation to drive progress within the industry.”

“Together, we want to contribute to the next generation of chassis systems and set standards for safety, performance, and sustainability” said Patrick Vith, CEO of thyssenkrupp Steering. “Our many years of experience as a major supplier in the steering sector will stand us in good stead.”

Under the agreement, BWI Group and thyssenkrupp Steering will leverage their strengths and expertise in safety-critical systems and software to bolster their collaboration. Both companies will accelerate the joint development of EMB systems as one important element of future vehicle motion control (VMC) solutions.

BWI Group brings more than a century of history and real-world R&D and production experience to the development of the new EMB product, including expertise in brakes and suspension systems. It serves more than 50 customers worldwide. The company also leverages its prior experience with EMB systems as Delphi in the 2000s.

thyssenkrupp Steering has been developing steer-by-wire technology for many years. The company contributes deep knowledge of new electrical/electronic (E/E) architectures and software, as well as its competence in electro-mechanical braking systems derived from steering technology.

Dr. Karsten Kroos, CEO of thyssenkrupp Automotive Technology said “Through partnerships like this one, we aim to develop competitive components for modern chassis systems serving the global automotive industry in an agile, innovative, and capital-efficient manner. Our focus is on synergies in technology and costs.”

Dr. Karsten Kroos, CEO of thyssenkrupp Automotive Technology said:

“Through partnerships like this one, we aim to develop competitive components for modern chassis systems serving the global automotive industry in an agile, innovative, and capital-efficient manner. Our focus is on synergies in technology and costs.”

Doug Carson, CTO of BWI Group said: “We have strong expectations in forging this strategic partnership with thyssenkrupp. Together, our brake-by-wire expertise will drive chassis technology breakthroughs that meet global standards and promote EMB adoption in Europe, North America, and Asia.”

EMB R&D will occur at BWI Group’s global R&D Centers located in Italy, Poland, U.S. and China, along with its Shanghai Software Center; thyssenkrupp’s technical centers in Hungary and Liechtenstein will also perform significant roles.

Pioneering full-dry EMB technology

The jointly developed EMB system is a premier offering that complements both companies’ controlled chassis portfolios. The two companies are now developing the third generation of EMB, a revolutionary technology that fulfills the need for simplified vehicle assembly while providing braking redundancy for Level 3 and above autonomous driving technologies.

Featuring a dual-motor design, efficient packaging, and novel redundancy, the newly developed EMB caliper ensures safety and reliability. Its reaction speed for time to wheel lock (TTL) is nearly twice as fast than modern one box wet brake systems. Additionally, it enables complete braking energy recovery and fully meets the electric and intelligent needs of braking systems for smart vehicles.

EMB is a visionary brake technology that eliminates the need for brake fluid while offering precise control with zero drag. It will become the definitive solution for future brake-by-wire technology, replacing current hydraulic calipers, and the accompanying One-Box and Two-Box brake actuation/modulation systems.

Globalized production anticipated in 2026

Looking ahead, the project plans to establish state-of-the-art automated production lines by 2025. Production and product delivery are expected to begin in 2026. BWI Group’s advanced automated production facilities worldwide will coordinate and expedite the mass production of EMB systems, ensuring this groundbreaking technology is available to a wide array of automakers worldwide.

Leveraging BWI Group’s nine manufacturing facilities and multiple proving grounds spread across key automotive centers in Asia, Europe, and North America, this cooperation regarding EMB systems, ensures efficient production and widespread distribution. Because the products are designed for worldwide markets, they will be manufactured to high standards to fulfill the variety of local demands and requirements.

Strong market growth ahead

EMB technology is becoming the focus of key automotive manufacturers, and it represents game-changing evolution for automotive chassis systems and the future demands of propulsion drive systems, electrification, performance, and sustainability. The jointly developed EMB caliper system underwent dynamic tests in Sweden, U.S. and China. Enthusiastic feedback and interests well as cooperation intentions were secured with major automakers in the three continents.

An industrial forecast projects that EMB calipers will contribute 13% of the total global braking market by 2035.