Vehicles are getting heavier and managing that weight has become a major challenge for chassis engineers. This is driven in large part by the surge in SUVs and the rise of BEVs. At the same time, drivers expect more from their cars: greater comfort, versatile functionality, and even off-road capability. We spoke with Bruno Perree, Engineering Manager at BWI Group, to find out how the latest update of Semi-Active Roll Control (SARC) is helping manufacturers deliver all of these demands without compromise.

Q: For those new to the technology, what exactly is SARC?

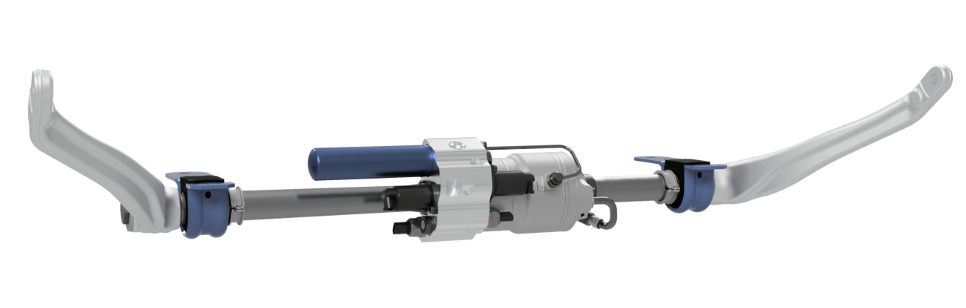

Bruno Perree: At its core, SARC is our hydraulic roll-control system that allows a vehicle’s stabiliser bar to connect or disconnect on demand. Traditional stabiliser bars force engineers into a compromise: make them stiff and you improve on-road handling, but you hurt comfort and off-road articulation. Make them softer and you improve comfort and mobility on rough surfaces, but the vehicle’s handling will be impacted.

SARC removes that compromise entirely. Our system uses a compact rotary actuator and a self-contained hydraulic mechanism to engage or disengage the bar in real-time. There’s no external pump or long pipework under the vehicle, so the packaging is neat and the power consumption is extremely low.

Q: What’s new in the latest version of SARC?

BP: The biggest step forward is the new ‘automatic mode’. Previously, the driver had to choose whether the bar was connected or disconnected via terrain modes. Now the system decides for itself.

It continuously monitors vehicle attributes such as steering angle, vehicle speed, lateral acceleration and yaw rate, and connects or disconnects the bar automatically. The bar can reconnect in under 200 milliseconds, so the transitions are completely transparent to the driver.

The key advantage here is that the vehicle can run disconnected almost all the time. It only needs the bar to be connected during cornering for handling or safety reasons. The rest of the time you get maximum comfort and full wheel articulation for better off-road capabilities.

Q: Why is that such a big benefit for OEMs?

BP: Essentially, this eliminates a compromise that chassis engineers have lived with for decades. It isn’t a particular issue for small city cars, but SUVs are big, heavy and have a high centre of gravity. To keep them stable, you need very stiff roll bars, so these applications are particularly prone to this compromise.

With more than half of all new registrations in Europe being SUVs it is a common problem for the industry now. SARC allows engineers to remove the compromise between handling and comfort and also provides the vehicle with much better off-road capabilities, which can be a competitive differentiator for OEMs.

Q: How has SARC been received by the end users?

The feedback from drivers has been extremely encouraging. When the Ford Bronco launched, which is equipped with SARC, journalists and early test-drivers quickly picked up on the switchable stabiliser bar and highlighted it as a key factor in the vehicle’s ride quality and off-road capability. We saw a similar reaction in China with Great Wall’s Tank 700 Hi4-T, which also uses SARC. The vehicle was very well received by both customers and the media, even winning a “Best Off-Road Award”.

Q: How does SARC improve off-road performance?

BP: When disconnected, the system provides zero roll stiffness. This is what you want for maximum wheel articulation, which is critical for traction. For example, on the Ford Bronco, the Ramp Travel Index (RTI), which is a measurement of axle articulation, increases by more than 20% when the bar is disconnected . When off-roading, this extra wheel travel can make the difference between getting stuck and getting out. This essentially means the left wheels are not restricted by what the right wheels are doing and vice versa. The hydraulic architecture is key here. It enables us to disconnect and reconnect under load as we have automatic centering. And because our design is sealed and self-contained, it’s extremely resistant to dirt and debris.

Q: How does SARC compare with other active roll-control technologies?

BP: SARC is the only hydraulic system on the market. This gives us the ability to connect and disconnect at any time, with a very fast response. That’s what makes our automatic mode possible. SARC is unique in being able to achieve this.

Most other solutions are mechanical. They rely on physical alignment to connect, so they often require some level of play to be designed into the system. That play is not good for steering feel, and the systems can’t connect and reconnect on the fly.

Q: What industry trends do you see boosting the adoption of SARC?

BP: There are a few clear shifts happening in the market that are making systems like SARC much more relevant. As previously mentioned, SUVs continue to dominate global sales, and the inherent weight and height issues associated with SUVs place a greater vehicle dynamics challenge that SARC can support.

Electrification is another clear trend. EVs are typically around 30% heavier than their ICE counterparts, making it more challenging to control body mass effectively. At the same time, BEV architectures make it easier to integrate an active roll system, as there are no exhausts or gearbox components in the way.

What’s interesting is that consumer expectations are also evolving. Drivers want more and more from their cars. They want vehicles that feel refined on long highway trips, stay flat and predictable on twisting roads, and real capability off-road. That’s a huge range of attributes to pack into one platform. These trends together are pushing manufacturers to look for smarter, more flexible ways of managing roll stiffness, and that’s exactly where SARC fits in. It gives them the control they need without forcing the compromises they’ve had to make in the past.

Q: What makes BWI Group so well placed to deliver SARC?

BP: BWI Group have been working on hydraulic roll-control technologies for more than two decades now, so we are very familiar with active roll control technologies. Over that time, we’ve developed and manufactured both linear and rotary actuator systems, and that depth of experience is what allows us to push the technology further with each generation.

We also supply some of the world’s largest and most demanding OEMs, which means our systems have to meet very high standards for performance, durability and refinement. And because we operate engineering and manufacturing sites across multiple regions, we’re able to support customers locally throughout development and into production. It’s that combination of long-term expertise, global capability and close collaboration with OEMs that really puts us in a strong position to deliver SARC.