The Software-Defined Vehicle (SDV) is moving the industry away from traditional hardware-led designs toward a future where software shapes, controls and enhances vehicle functionality, safety and user experience. This shift to more connected systems opens up new opportunities for digitised suspension technologies, such as MagneRide®. We sat down with Yuan Zamparini, Global Chief Engineer for Controls, Electronics & Software for Controlled Suspensions at BWI Group, to explore this further.

Q: What is MagneRide and how is it digitally controlled?

YZ: MagneRide is a semi-active suspension system that uses a magnetic field to energise the magnetorheological fluid, which is filled with iron particles. When a magnetic field is applied, those iron particles align to form a new structure and change the fluid’s viscosity, which alters the damping force. What makes this particularly relevant for software-defined vehicles is that MagneRide is fully and continuously digitally controlled in a wide range of damping forces with millisecond response times.

As is common with premium technologies, MagneRide found its first applications in high-performance vehicles. But as the industry shifts towards the Software Defined Vehicle and the demand for digital control increases, MagneRide is now being fitted to all types of vehicles, from mid-range sedans to large BEV SUVs.

Q: How does this digital control advantage translate to SDV applications?

YZ: The key differentiator is that the system, once base damping characteristics are set, is completely tuneable in software. Unlike solenoid-based semi-active systems that require hardware modifications to change suspension characteristics, MagneRide can be completely recalibrated through the ECU. It enables manufacturers to fully customise settings for regional markets, for example, perhaps to make the vehicle more compliant for North American preferences or sportier calibrations for European drivers. This would simply be too expensive if hardware changes were necessary. We have the capability for over-the-air (OTA) updates, so manufacturers can adjust suspension tuning post-production if required, cost-effectively.

Q: What new functionalities does SDV architectures unlock for MagneRide?

YZ: MagneRide’s response times are one of the quickest on the market and it can adjust to road inputs almost instantaneously. However, we have also developed a new preview function. By integrating with the vehicle’s perception system, which is now possible thanks to SDV architectures, we can use cameras and radar to evaluate road surfaces ahead and prime the dampers accordingly. For example, if we detect a pothole or sharp corner approaching, the damping characteristics can be pre-adjusted to optimise the performance. We have also developed a real-time arbitration system that weighs this ‘preview’ information against the ‘instantaneous’ inputs to determine the optimal response. This ultimately increases the performance of the suspension and gives OEMs more flexibility.

This integration can also be used to optimise the suspension in emergency situations. For example, if automatic emergency braking is triggered, the suspension system can instantly adjust itself to improve braking distances and control. The improvement is only a safety enhancement, not a mitigation mechanism, but in life and death situations, every advantage matters.

Q: How do you see the relationship between traditional automotive suppliers and OEMs evolving in the SDV era?

YZ: The relationship is becoming more collaborative and integrated. Rather than simply supplying individual components, we’re becoming development partners. We are contributing to the fundamental changes which are happening to the vehicle architecture. This requires deeper technical integration and long-term partnerships, but it also enables solutions that are much more optimised for the complete vehicle system rather than individual components. We are also responding to an increased demand for a more modular approach to delivery. OEMs want to be able to pick and choose elements of the solution that best fit their architecture.

Q: What does the move toward modularity mean for suppliers and OEMs?

YZ: BWI Group is focusing on providing flexible modular solutions that can integrate with both the OEM’s central controller and the zone controller. Depending on their specific needs and existing subsystems, customers can choose different combinations of our hardware, software modules or integration services. This approach gives OEMs more control over their vehicle architecture while still benefiting from our specialised expertise in suspension control algorithms, hardware and software.

Q: Are there any SDV partnerships with OEMs that you can discuss?

YZ: We’re currently involved in a co-development program with a major US OEM for their first SDV platform. The customer established their SDV development roadmap back in 2021 and, given our long-standing relationship and the central role MagneRide plays in the SDV architecture, they invited us to participate from the beginning. They have now built prototypes for benches and vehicles and we have supplied the entire digital suspension ecosystem; including the dampers, algorithm in the central controller, smart actuator controller with Ethernet capability, and associated sensors.

Q: What were the main technical challenges in adapting to an SDV architecture?

YZ: One of the biggest challenges was integrating real time-controlled systems to the new Ethernet communication architecture. The complexity comes from coordinating multiple digital systems while maintaining the real-time response capabilities our solutions have become famous for and are critical for suspension performance. We have used a parallel approach by developing a level 4 virtual model and physical prototypes, and we’re now on our production infrastructure-ready generation of sample.

Q: SDV is transforming all aspects of vehicle design. How is it affecting chassis systems in particular?

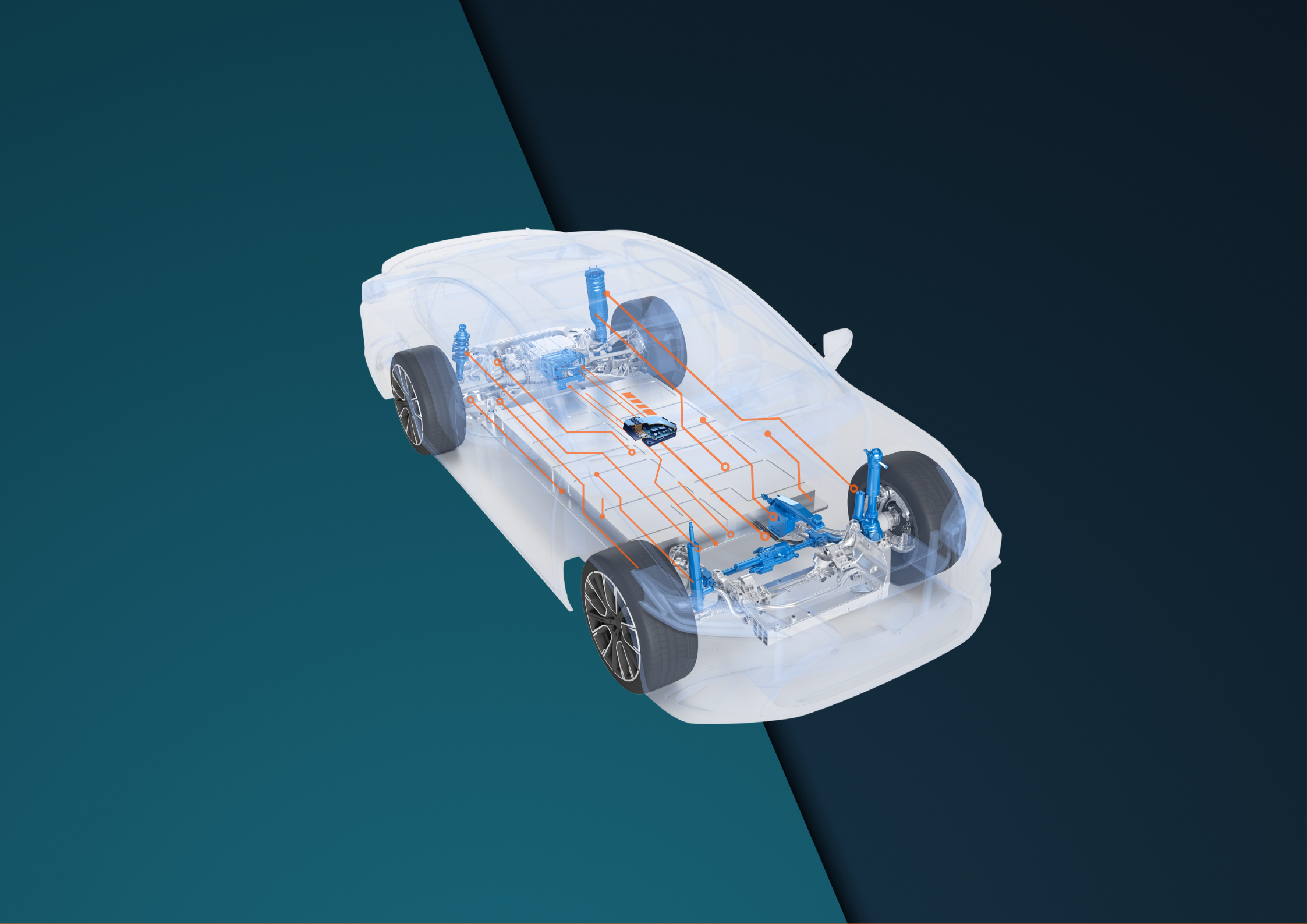

The most obvious shift is that all systems are becoming more connected and software-driven. Instead of treating each feature separately, SDV architectures allow a central controller to manage them collectively and cooperatively, making the chassis control a truly integrated part of the vehicle’s ecosystem. This is opening up massive possibilities for OEMs and is where MagneRide’s large scale of controllability has an advantage.

Q: How is artificial intelligence being integrated into the latest MagneRide systems?

YZ: A high potential area for the new generation development would be an AI-based self-learning tuning system. MagneRide is tuned using an array of parameters and inputs and varies significantly based on vehicle type, size and intended use. This AI system dramatically reduces both the cost and time required for tuning and testing, which was already faster than solenoid valve-based systems, while ultimately delivering better performance through continuous learning and optimisation.

Q: Beyond suspension dampers, how is BWI Group positioning itself in the SDV space?

YZ: We identified the SDV trend early and have been developing complementary digitally-controlled solutions. Alongside MagneRide, we offer semi-active stabiliser bar systems, Four corner Air Suspension control systems, hydraulic lift systems, magnetorheological powertrain mounts and electric braking systems. The advantage is that all these chassis subsystems can work coordinatively and contribute to the fundamental functions of Chassis and body control, sharing inputs and processing functions. This creates opportunities for holistic chassis optimisation that wouldn’t be possible with traditional, isolated systems.